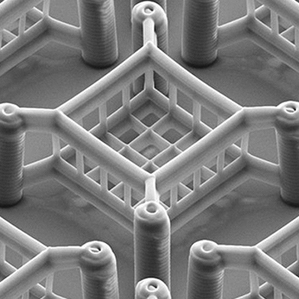

3D printing is a cool technology and one I’m really enjoying…but this 3D microprinter is in a class by itself. It can print features as small as 30 nanometers, which is about .000001″! It uses a process similar to stereo lithography, whereby a liquid resin is hardened by directed light in selective areas, building the part a layer at a time. Producing geometry at this scale can be useful for all your favorite nano-technologies…microneedles, microfluidics, etc. Cool stuff.

3D printing is a cool technology and one I’m really enjoying…but this 3D microprinter is in a class by itself. It can print features as small as 30 nanometers, which is about .000001″! It uses a process similar to stereo lithography, whereby a liquid resin is hardened by directed light in selective areas, building the part a layer at a time. Producing geometry at this scale can be useful for all your favorite nano-technologies…microneedles, microfluidics, etc. Cool stuff.

(read more here)